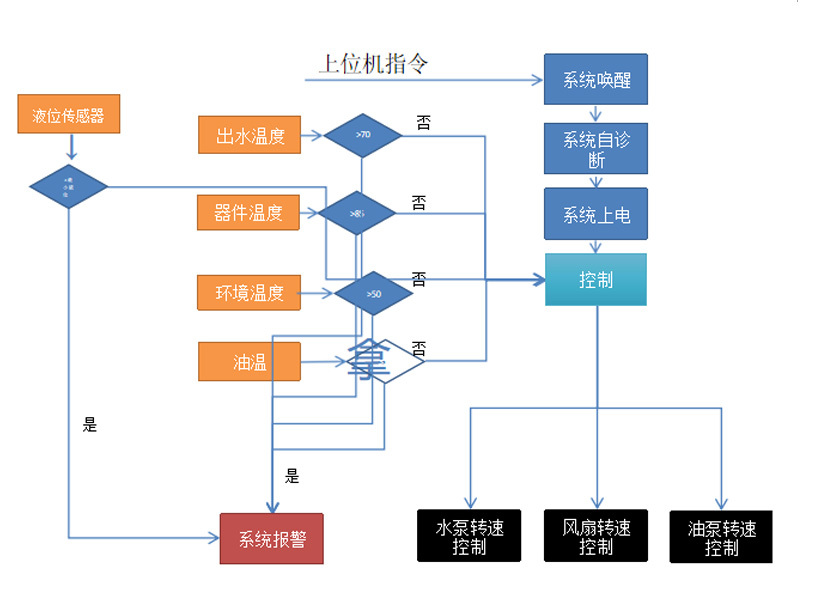

Control therory

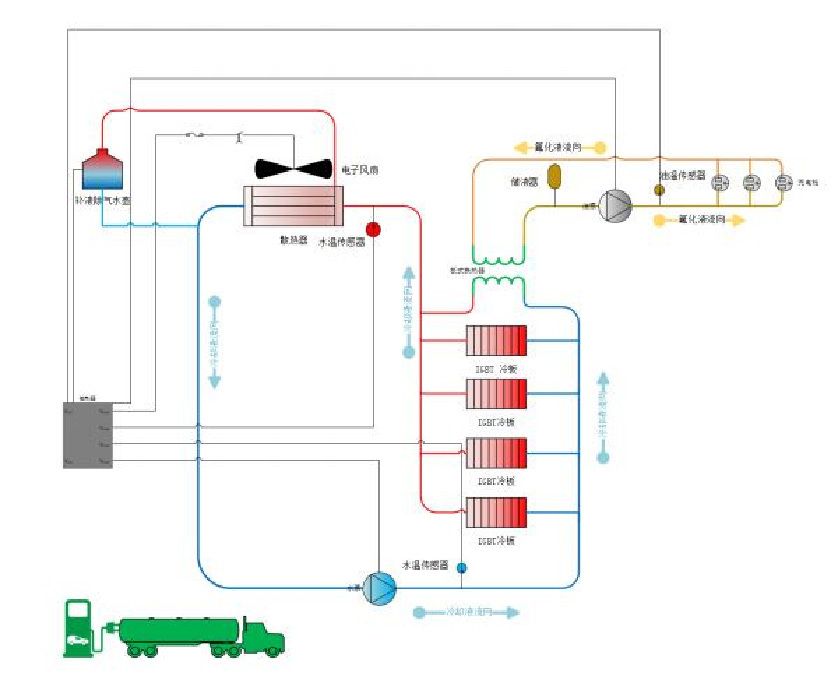

- The liquid cooling system of the charging station mainly includes a circulating water pump, liquid cooling plate, radiator, electronic fan, as well as electronic oil pump and plate heat exchanger.

- The integrated liquid cooling system effectively improves the integration of charging stations, reduces the design difficulties of charging module air ducts, and reduces the volume of charging stations. At the same time, it is beneficial to improve the protection level of charging piles. Prevent the impact of water, dust, insects, etc. on the lifespan of charging stations, reduce maintenance cycles, and enhance user experience.

- The high convective heat transfer coefficient and uniform temperature performance of liquid cooling systems reduce the difficulty of circuit design.

- Adopting a side in and side out approach ensures that each component in the circuit has an equivalent flow length and converging flow resistance, thereby ensuring the uniformity of flow distribution.

- Adopting a quick plug structure to enhance product modularity and installation convenience.

- The design can be freely expanded to meet the needs of different power piles.

System Principle

The system adopts variable frequency fans and water pumps to meet the heat exchange requirements of the charging module under different charging conditions and improve the maximum energy efficiency characteristics of the system.

-

At low load:

Reduce fan and consumption speed, lower noise and energy consumption.

-

During high load:

Increase the fan speed, suitable water pump speed, and seek optimal energy efficiency, NVH, and durability performance.

-

When the system leaks:

When the coolant level is below the minimum water level, the system sends a safety warning to the upper computer to prevent charging faults.

-

When the water temperature is too high:

When the water temperature is too high, an alarm will be sent to the upper computer to reduce the charging power, ensuring the safety and reliability of the system.

-

When the ambient temperature is too high:

If the ambient temperature is too high, remind the system to reduce the charging output power

Device characteristics

| Sequence | Device | Function | Type | Protection grade | RHOS |

| 1 | Radiator | Air-cooled convective heat exchanger | Tube type | NA | 2 |

| 2 | Water pump | Charging station water cycle | AC220/DC24V | IP67 | 2 |

| 3 | Cold plate | IGBT heat exchanger | Welding type | NA | 2 |

| 4 | Fan | Forced ventilation device | AC220/DC24V | IP54 | 2 |

| 5 | Board replacement | Oil-water heat exchanger | Aluminum sheet metal | IP67 | 2 |

| 6 | controller | system controller | PCBA | IP54 | 2 |

| 7 | Water temperature sensor | Temperature detection | 5V DC | IP67 | 2 |

| 8 | Environmental temperature sensor | Temperature detection | 5V DC | IP67 | 2 |

| 9 | Oil pump | Charging gun fluorinated oil circulation device | DC 24V | IP67 | 2 |

| 10 | oil temperature sensor | Temperature detection | 5V DC | IP67 | 2 |

Water circulating pump

Liquid cooled structure compared to air-cooled structure, effectively reducing space

Use to improve the heat transfer coefficient of the system. The system will become more compact, solving the space waste caused by air duct layout and saving resources for the installation of charging stations.

Device characteristics

| Sequence | Device | Function | Type | Protection grade | RHOS |

| 1 | Radiator | Air-cooled convective heat exchanger | Tube type | NA | 2 |

| 2 | Water pump | Charging station water cycle | AC220/DC24V | IP67 | 2 |

| 3 | Cold plate | IGBT heat exchanger | Welding type | NA | 2 |

| 4 | Fan | Forced ventilation device | AC220/DC24V | IP54 | 2 |

| 5 | Board replacement | Oil-water heat exchanger | Aluminum sheet metal | IP67 | 2 |

| 6 | controller | system controller | PCBA | IP54 | 2 |

| 7 | Water temperature sensor | Temperature detection | 5V DC | IP67 | 2 |

| 8 | Environmental temperature sensor | Temperature detection | 5V DC | IP67 | 2 |

| 9 | Oil pump | Charging gun fluorinated oil circulation device | DC 24V | IP67 | 2 |

| 10 | oil temperature sensor | Temperature detection | 5V DC | IP67 | 2 |

Modular takeover method

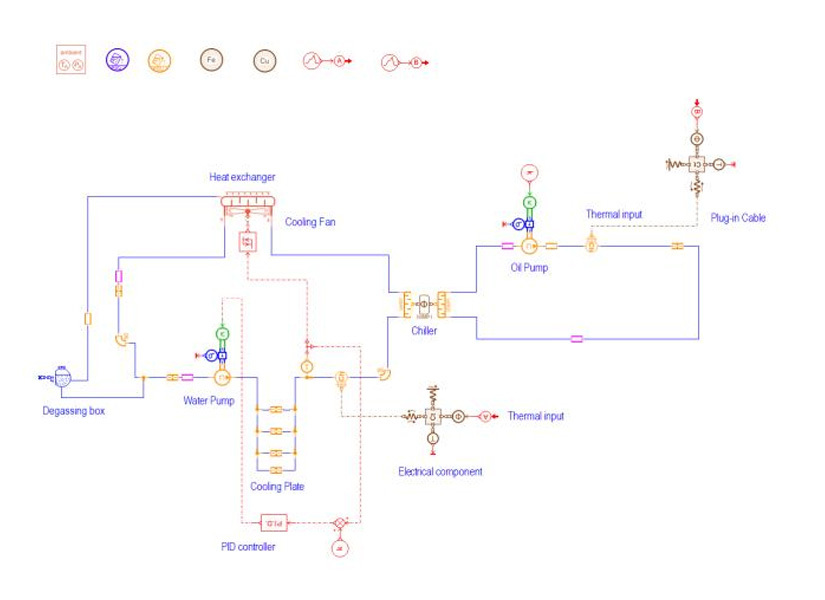

Platform based simulation model:

- Reserve coolant inlet and outlet ports to effectively solve the difficulties in waterproof and dustproof design of the system;

- The charging module is miniaturized and lightweight;

- No need for air ducts, modular design is simpler;

- Adopting a quick plug installation structure to improve efficiency and reduce process costs;

- PA12 integrated cooling pipeline, used for cooling pipelines in new energy vehicles, with high reliability;

- Quick plug sealing ensures consistent assembly quality.

Computational simulation

Angpai module liquid cooling module:

Based on platform based simulation models, quickly analyze the actual performance of system selection. Effectively improve development speed and anticipate risks in advance. Products of the same series can be simulated and calculated on the same platform, with complete parameterized design and higher reliability.

The simulation system includes:

-

Cabinet system heat exchange

-

Heat exchange performance of charging gun

-

Oil circuit resistance characteristics

-

Flow resistance characteristics of waterways