Manufacturing Advantages

3 Pre-Process Lines

- Assembly and welding radiator

- Pump PCBA welding and assembly

- Welding and assembly cold plates

- Tube assembly

Capacity

- 3 Automatic production line

- Six High efficiency FATP lines for Assembly/Leak test/Thermal Resistancetesting

- Two Pre-Process Lines

- 2 millions output of Liquid Cooling Module /Annual

- 3 millions of DC Fan / Annual

Paost-end assembly lines

Operator

Production / test equipment

Production Process

IPQC、Procedure、 FQC

Annual output /PCS

IDC Business Unit

100000 level dust-free lines

- Hot melting equipment

- Vacuum dryer machine

- Nitrogen filling machine

- Helium leak detection system

- Thermal resistance testerSuper sonic clearing machine

300k output/Month

Equipments

Liquid injection Machine

Thermal Resistance testing

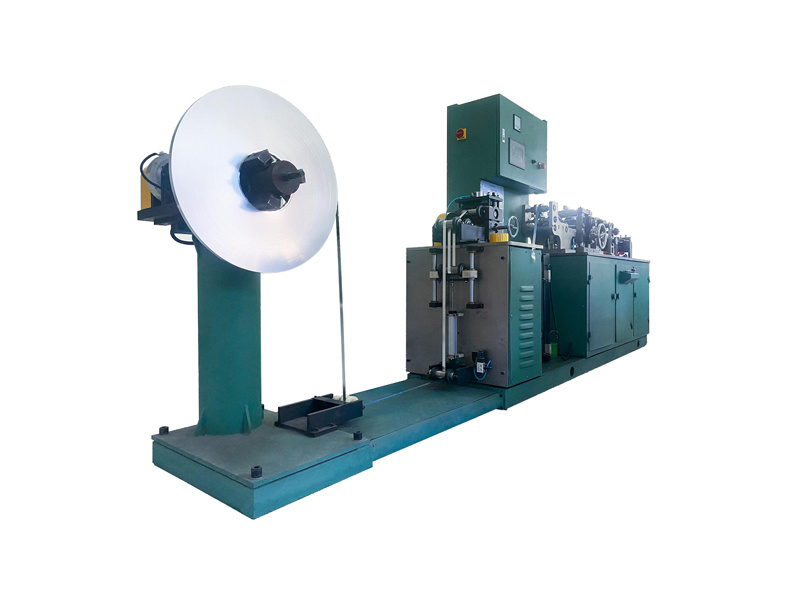

Radiator fin forming machine

Cu Brazed Machine

Al Brazed Machine

Vacuum Brazing

2907-2908, Building 2, OCT Creative Building, Minzhi Street, Longhua District, Shenzhen,China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

COPYRIGHT 2024 Apaltek Co., Ltd.ALL RIGHTS RESERVED

Powered by 300.cn